The exhaust on my Jaguar XJ6 X300 started blowing quite badly. I thought it may be time to replace the whole exhaust since I have patched up the rear boxes once before. I decided that I would buy a complete stainless steel system, so I looked around for some prices. I have previously fitted a full stainless system on my XJ-S that I purchased from Sterling Exhausts (now called G.E.S. Exhausts) in Wales. I was very happy with this system and found that their price for an exhaust for XJ6 was also competitive. After further investigation the current problem with my exhaust turned out to be on the down pipe and the section following the down pipe. These two sections contain the catalytic converters and are actually not included in the prices I received from the stainless steel exhaust suppliers. I am not completely certain, but judging by the condition of these sections of exhaust, they may well be made out of stainless steel already.

I decided to remove the down pipe to see if I could repair the fault. I loosened the nuts holding the down pipes to the manifolds, which was a lot easier than I thought it would be. Three of them were easily accessible from beneath using a socket and long extension bars. The fourth nut could only be undone from above using an open spanner. Once I was happy that these nuts could be loosened I cut through the bolt that tightens the clamp connecting the down pipe to the next section of pipe.

The photo above shows the down pipes removed from the car with the oxygen sensors still fitted. Before disconnecting the oxygen sensors, I wrapped a piece of tape around one of the connectors and the corresponding socket it was connected to, since it is essential to reconnect them in the correct sockets.

This photos shows the location of one of my problems. The welded joint had cracked, presumably due to stress over the years. This problem fits well with the symptoms I was experiencing. When the engine was first started from cold, the exhaust would make a lot of noise, but would then quieten down as the exhaust heated up and the crack closed up.

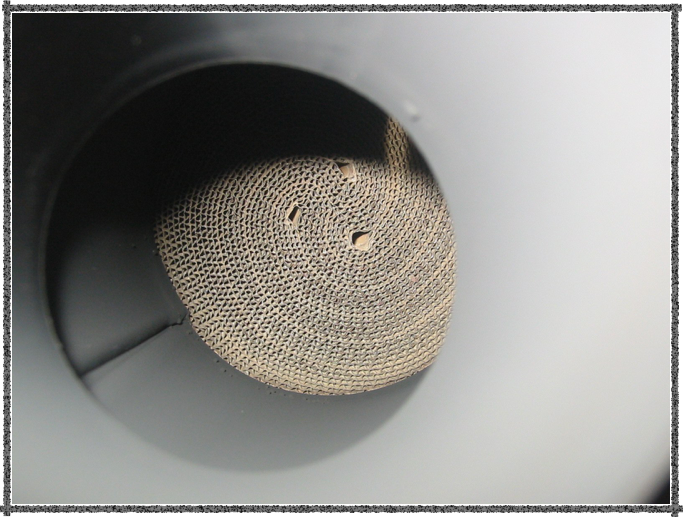

While I had the down pipes off the car, I had a look at the catalytic converters to see if they were restricting the gas flow due to damage or blocked by soot etc. These two photos show that they were very clean.

I welded the crack using my mig welder loaded with a reel of stainless steel filler wire.

Unfortunately this was not my only problem with the exhaust. The joint on the next section of pipe that contains two more catalytic converters was also badly cracked. This time I decided to cut about 8cm of damaged pipe off and replace it with a tube of stainless steel made by wrapping a piece of sheet stainless steel into a tube.

The section of damaged pipe removed and then the new stainless steel tube welded in place. It was now just a matter of refitting the downpipes and reconnecting the oxygen sensors. Starting the engine now revealed a quieter exhaust system.

Looking at the condition of the rest of the exhaust, I have decided to just purchase a new pair of rear stainless steel boxes, since the other two non catalyst boxes still look in good condition.