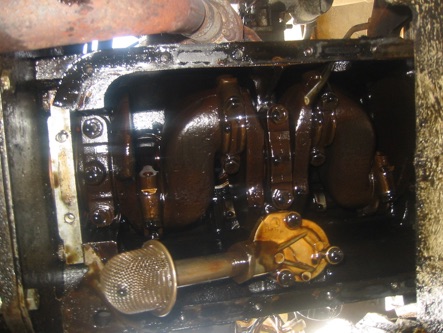

For a while now I have had a small engine oil leak on my Triumph Spitfire. Owners of these cars may well say that this is normal which would be supported by many comments found on the internet.

I decided that I had cleaned the park at work too many times and now was the time to stop the oil leak. Unfortunately this turned out to be more difficult than I imagined.

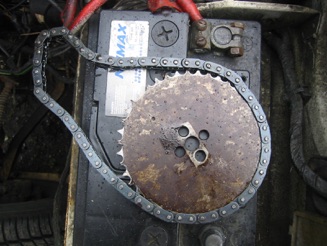

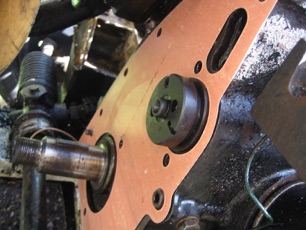

It looked to me like the timing cover gasket was where the oil was escaping, so I purchased a timing cover gasket and a crank front oil seal.